ASTM A194 Gr 2H Nut

Gr. 2H Rivet Nuts, ASTM A194 Gr. 2H Hex Nuts, A194 Grade 6 T Nuts, A194 Grade 2H Sleeve Nuts, Grade 2H Metric Nuts.

Carbon steel is used to create the high tensile ASTM A194 Grade 2H Nut. High strength and corrosion resistance characterize the material. These a194 2h grade square nuts and other nuts are made by the renowned company fas10. The spec is for high strength, mechanically threaded nut produced by carbon steel.

The material is composed of silicon, carbon, phosphorus, manganese, and sulfur. These fasteners come in a variety of varieties and can be made by cold forging, hot forging, or machining, like the ASTM A194 Grade 2H Nuts in this specification. These nuts are made from the heat-treated stock of the a194 two h substance and have a particular toughness, heating process, and chemical composition. The marginal size of the nuts can range from ¼ – 1 ½ inches, and there are somewhere between 8 – 20 threads per inch.

About ASTM A194 Gr 2H Nut

2H Acorn Nuts, SA194 2H Captive Nuts, 2H Grade 12-Point Nuts, ASME SA194 2H Nyloc Nuts, ASTM A194 2H Dome Nuts.

Based on the nut size, the Brinell hardness of SA194 Grade 2H Self-lock Nuts and other nuts ranges from 212 – 327 BHN. At 455° C, the tempered and quenched heating procedure is conducted. Several kinds, such as grade 2h square nuts, are utilized to join two major components. The nuts’ tensile strength ranges from 150 KSI – 175 KSI. As a prominent manufacturer, we produce nuts in all sizes, forms, and varieties. For more details about the many kinds of SA 194 grade 2H nuts and the cost, don’t hesitate to get in touch with us.

ASTM A194 Gr 2H Nut Specification

| Dimensions | ASME B18.2.1, B18.3 |

| Melt Origin | Soutd America/East Europe/Japan/Korea/ |

| Product Origin | Made in India |

| Threads Configuration | ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Mandatory Requirements | Free from Mercury & Radioactive Contamination |

| Additional Requirements | NACE MR0103 / MR0175 / ISO 15156 Compliance |

Chemical Composition ASTM A194 Gr 2H Nut

| ASTM | C. | Mn. | Si. | P. | S. | Cr. | Ni. | Mo. |

| A194 Grade 6 | 0.15% | 1% | 1.00% | 0.04%. | 0.03% | 11.5 - 13.5% | -- | -- |

Mechanical Properties ASTM A194 Gr 2H Nut

| Tensile Strength/Ultimate Tensile Stress (UTS) – (Mpa) | Yield Strength/Proof Stress(0.2% Offset) (YS) – (Mpa) | Elongation in 4D (El) | Reduction | Hardness – (BHN) |

| 550 | 240 | 30 | 40 | 223 |

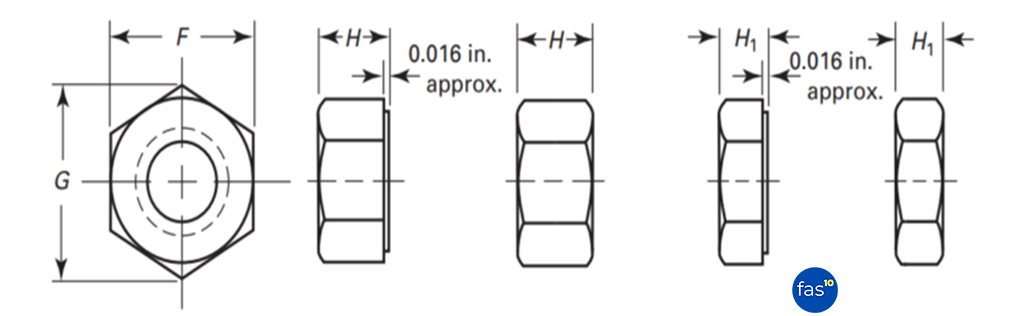

Dimensions Of ASTM A194 Gr 2H Nut

ASTM A194 Gr. 2H Nut Dimensions :

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

Different Types Of ASTM A194 Gr 2H Nut

Different Types Of Nuts:

ASTM A194 Gr. 2H Hex Nuts

ASTM A194 Gr. 2H T Nuts

ASTM A194 Gr. 2H Metric Nuts

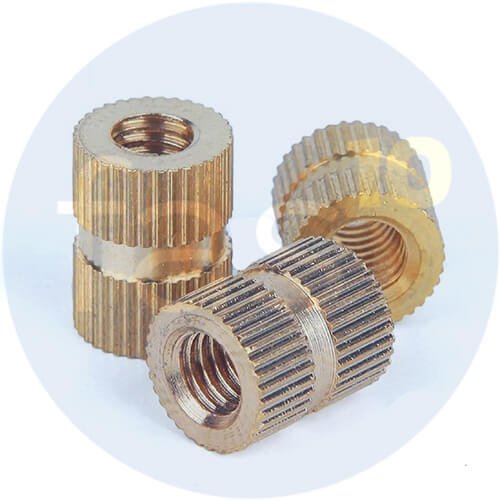

ASTM A194 Gr. 2H Rivet Nuts

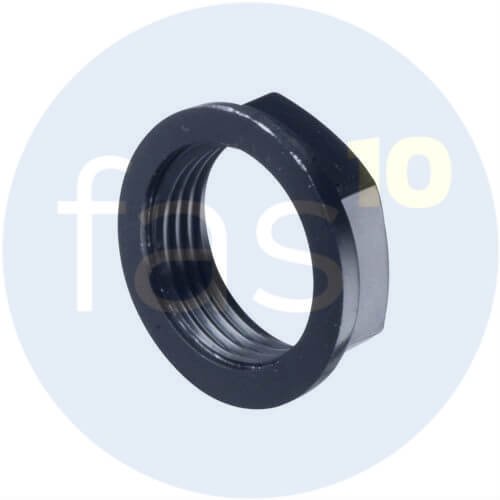

ASTM A194 Gr. 2H Sleeve Nuts

ASTM A194 Gr. 2H 12-Point Nuts

ASTM A194 Gr. 2H Lug Nut

ASTM A194 Gr. 2H Captive Nuts

ASTM A194 Gr. 2H Dome Nuts

ASTM A194 Gr. 2H Acorn Nuts

ASTM A194 Gr. 2H Nyloc Nuts

ASTM A194 Gr. 2H Insert Nuts

ASTM A194 Gr. 2H Lock Nuts

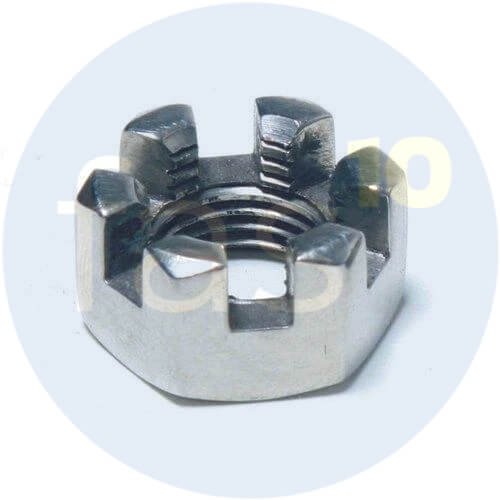

ASTM A194 Gr. 2H Castle Nuts