ASTM F594 Nut

ASTM F594 Grade Nyloc Nuts, Grade F594 12-Point Nuts, Gr F594 Rivet Nuts, ASTM F594 Lug Nut, Grade F594 Acorn Nuts.

When manufacturing ASTM F594 Nuts, many different alloys may be utilized. The most common types of alloys are austenitic, ferritic, martensitic, and precipitation-hardened forms. Grades 303 through 630 are represented in the materials, along with grades 304, 305, and 303. The markings found on ASTM F594 hex nuts and other nuts provide information regarding the state of the nut. Because of their long lifespan and adaptability across various contexts, hex nuts are consistently ranked as the most preferred option for fasteners. Depending on the quality of the material, The proof stress of hex nuts ranges from 75,000 to 100,000 ksi. Along with bolts and nuts, the Grade F594 12-Point Nuts is one of the key pieces of hardware utilized most of the time.

About ASTM F594 Nut

Gr F594 Captive Nuts, ASTM F594 Metric Nuts, ASTM F594 Grade Sleeve Nuts, Grade F594 T Nuts, ASTM F594 Grade Hex Nuts.

When bolts and nuts need to be tightened from a distance, using a nut is a valuable item. The difficulty of cracking nuts can be determined by the material they are made of and the nuts’ size. Because of their low cost, high strength, and resistance to general corrosion, F594 hex nuts are the material most frequently utilized of all available options. Elements such as manganese, carbon, phosphorus, silicon, sulfur, chromium (18%), nickel (8%), and up to 1% copper are added to the substance’s composition to make the material more resistant to corrosion. For resistance against the accumulation of tension caused by chloride ions, the 316 grade contains up to 3% molybdenum. We are a leading supplier, and the ASTM F594 Heavy Hex Nut is only one of the many different kinds of nuts that we offer.

ASTM F594 Nut Specification

| Standards | Designation |

| ASTM | F594 |

| Astm F594 Nuts Delivery time | custom product will according to special requirement, Regular product is about 7-15 days |

| ASTM F594 Nuts Coatings | Cadmium, Black Oxide, Teflon, Galvanized, Zinc, Xylan, Otders Upon Request |

| Astm F594 Nuts Dimensions | ASME B18.3, B18.2.1 |

| Melt Origin | Soutd America/East Europe/Japan/Korea |

| Product Origin | Made in India |

| Astm F594 Nuts Certification | Dual Certified As per ASME & ASTM Codes |

| Additional Certifications | Merkblatt AD 2000 W2 Certified,PED 97/23/EC Certified |

| Mandatory Requirements | Free from Radioactive & Mercury Contamination |

| Additional Requirements | NACE MR0175 / MR0103 /ISO 15156 Compliance |

| Astm F594 Nuts Samples | Yes |

| Payment Terms | Western Union, T/T, Paypal, Trade Assurance 30% deposit & balance before shipping or L/C |

Chemical Composition ASTM F594 Nut

| UNS Designation | Alloy Group | Alloy | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Copper | Molybdenum | Otders |

| S30200 | 1 | 303 | 0.15 | 2.00 | 0.200 | 0.150 min | 1 | 17.0 – 19.0 | 8.0 – 10.0 | — | 0.60 maxA | — |

| S30323 | 1 | 303 Se | 0.15 | 2.00 | 0.200 | 0.060 | 1 | 17.0 – 19.0 | 8.0 – 10.0 | — | — | Se 0.15 min |

| A30400 | 1 | 304 | 0.08 | 2.00 | 0.045 | 0.030 | 1 | 18.0 – 20.0 | 8.0 – 10.5 | 1.00 | — | — |

| S30403 | 1 | 304 L | 0.03 | 2.00 | 0.045 | 0.030 | 1 | 18.0 – 20.0 | 8.0 – 12.0 | 1.00 | — | — |

| S30500 | 1 | 305 | 0.12 | 2.00 | 0.045 | 0.030 | 1 | 17.0 – 19.0 | 10.5 – 13.0 | 1.00 | — | — |

| S38400 | 1 | 384 | 0.08 | 2.00 | 0.045 | 0.030 | 1 | 15.0 – 17.0 | 17.0 – 19.0 | — | 0.50 maxA | — |

| S20300 | 1 | XM1 | 0.08 | 5.00 – 6.50 | 0.040 | 0.18 – 0.35 | 1 | 16.0 – 18.0 | 5.0 – 6.5 | 1.75 – 2.25 | — | — |

| S30430 | 1 | 18-9LW | 0.10 | 2.00 | 0.045 | 0.030 | 1 | 17.0 – 19.0 | 8.0 – 10.0 | 3.0 – 4.0 | — | — |

| S30433 | 1 | 302HQ | 0.03 | 2.00 | 0.045 | 0.030 | 1 | 17.0 – 19.0 | 8.0 – 10.0 | 3.0 – 4.0 | — | — |

| S31600 | 2 | 316 | 0.08 | 2.00 | 0.045 | 0.030 | 1 | 16.0 – 18.0 | 10.0 – 14.0 | — | 2.0 – 3.0 | — |

| S31603 | 2 | 316 L | 0.03 | 2.00 | 0.045 | 0.030 | 1 | 16.0 – 18.0 | 10.0 – 14.0 | — | 2.0 – 3.0 | — |

| S32100 | 3 | 321 | 0.08 | 2.00 | 0.045 | 0.030 | 1 | 17.0 – 19.0 | 9.0 – 12.0 | — | — | Ti 5 x C min |

| S34700 | 3 | 347 | 0.08 | 2.00 | 0.045 | 0.030 | 1 | 17.0 – 19.0 | 9.0 – 13.0 | — | — | Cb+Ta 10 x C min |

| S43000 | 4 | 430 | 0.12 | 1.00 | 0.040 | 0.030 | 1 | 16.0 – 18.0 | — | — | — | — |

| S43020 | 4 | 430F | 0.12 | 1.25 | 0.060 | 0.150 min | 1 | 16.0 – 18.0 | — | — | 0.60 maxA | — |

| S41000 | 5 | 410 | 0.15 | 1.00 | 0.040 | 0.030 | 1 | 11.5 – 13.5 | — | — | — | — |

| S41600 | 5 | 416 | 0.15 | 1.25 | 0.060 | 0.150 min | 1 | 12.0 – 14.0 | — | — | 0.60 maxA | — |

| S41623 | 5 | 416 Se | 0.15 | 1.25 | 0.060 | 0.060 | 1 | 12.0 – 14.0 | — | — | Se 0.15 min | — |

| S43100 | 6 | 431 | 0.20 | 1.00 | 0.040 | 0.030 | 1 | 15.0 – 17.0 | 1.25 – 2.50 | — | — | — |

| S17400 | 7 | 630 | 0.07 | 1.00 | 0.040 | 0.030 | 1 | 15.0 – 17.5 | 3.0-5.0 | — | — | Cb+Ta 0.15 – 0.45 |

Mechanical Properties ASTM F594 Nut

| Grade | Style | Size, in. | Proof Load, ksi | Hardness, HBN | |

| Plain | Galvanized | ||||

| A | Hex | 1/4 – 1-1/2 | 90 | 68 | 116 – 302 |

| Heavy Hex | 1/4 – 4 | 100 | 75 | 116 – 302 | |

| B | Heavy Hex | 1/4 – 1 | 133 | 100 | 121 – 302 |

| Heavy Hex | 1-1/8 – 1- 1/2 | 116 | 87 | 121 – 302 | |

| C / C3 | Heavy Hex | 1/4 – 4 | 144 | 144 | 143 – 352 |

| D | Heavy Hex | 1/4 – 4 | 150 | 150 | 248 – 352 |

| DH / DH3 | Heavy Hex | 1/4 – 4 | 175 | 150 | 248 – 352 |

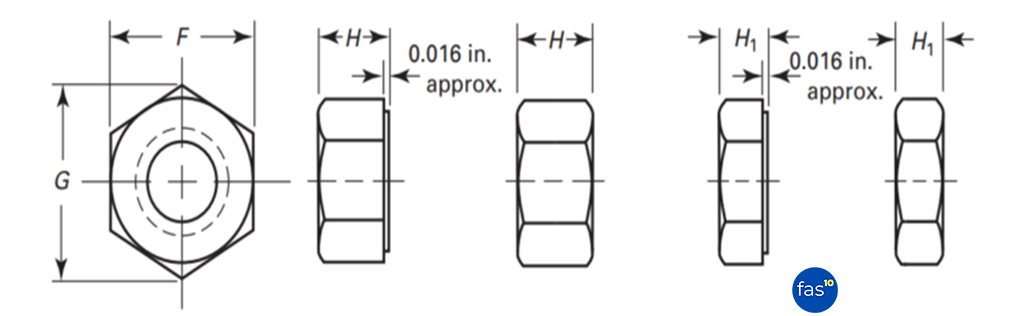

Dimensions Of ASTM F594 Nut

ASTM F594 Nut Dimensions :

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

Different Types Of ASTM F594 Nut

Different Types Of Nuts:

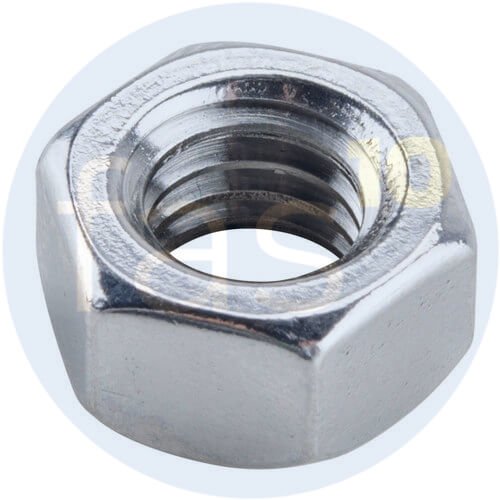

ASTM F594 Hex Nuts

ASTM F594 T Nuts

ASTM F594 Metric Nuts

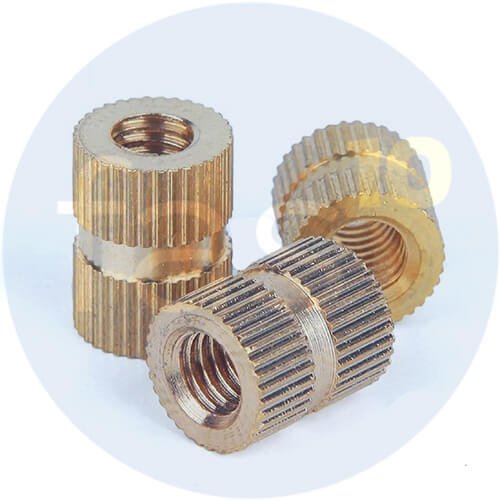

ASTM F594 Rivet Nuts

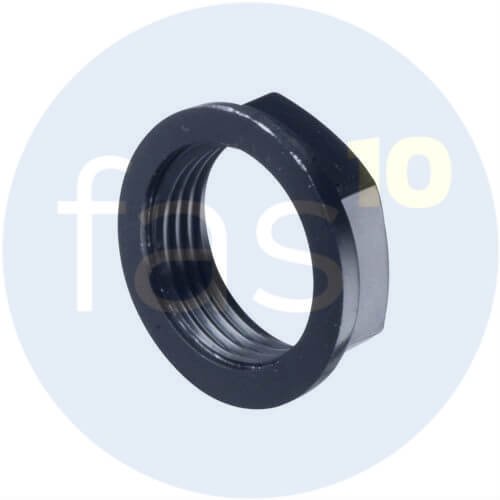

ASTM F594 Sleeve Nuts

ASTM F594 12-Point Nuts

ASTM F594 Lug Nut

ASTM F594 Captive Nuts

ASTM F594 Dome Nuts

ASTM F594 Acorn Nuts

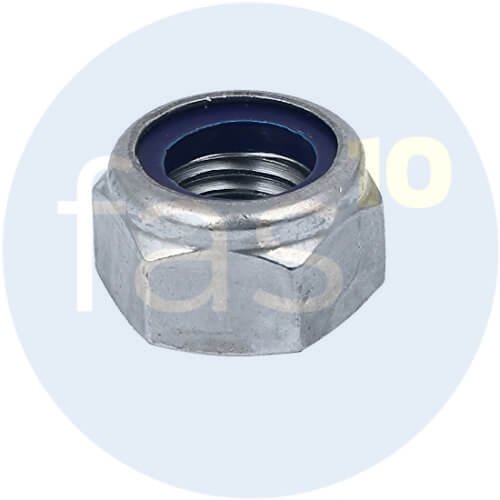

ASTM F594 Nyloc Nuts

ASTM F594 Insert Nuts

ASTM F594 Lock Nuts

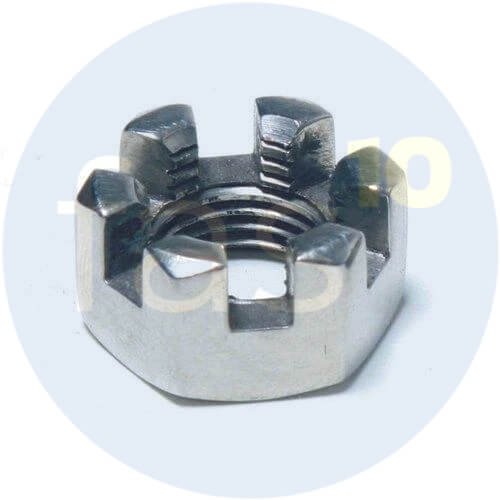

ASTM F594 Castle Nuts