Nickel Alloy 201 Bolt

Nickel Alloy 201 Eye Bolt, DIN 2.4066 Hex Head Bolt, Alloy 201 Anchor Bolt, Nickel 201 Hex Bolt, ASTM B564 Nickel 201 U Bolt, UNS N02201 Flange Head Bolt, WNRF 2.4068 Stud Bolt, ASME SB564 Nickel 201 Allen Bolt.

fas10 is a prominent manufacturer and supplier of Nickel Alloy 201 Bolt. It Contains With a minimum tensile strength of 403 MPa and a minimum yield strength of 103 MPa after annealing, nickel 201 fasteners are likewise robust, although not as strong as the 201 alloys. The Nickel 201 Fasteners are utilized in situations when they cannot be used. The screws are simple to install and maintain since they don’t need nuts to keep them in place. The connections are tightened by using the Nickel 201 Washer in conjunction with other fasteners. At room temperature, our Nickel 201 Fasteners are resistant to dry gases, acids, and alkalis. Depending on the temperature and solution concentration, they are also resistant to mineral acids. High thermal and electrical conductivity is provided by DIN 2.4066 Hex Head Bolt, which may be used in service over 600 degrees Fahrenheit (316 degrees C).

Alloy 201 Anchor Bolts are constructed using the nickel grade’s low-carbon version. It is mostly used for the assembling of machine parts that need strong magnetic and great corrosion-resistant qualities. It has wrought-grade purity nickel and exceptional ductile properties. These fasteners have a high degree of thermal and electrical conductivity and are ferromagnetic. For leveraging the high concentration of reducing and oxidizing conditions, they are the finest options.

About Nickel Alloy 201 Bolt

UNS N02201 Hex Head Bolt, DIN 2.4066 Hex Bolt, Werkstoff Nr. 2.4068 Eye Bolt, ASTM B564 Nickel 201 Anchor Bolt, Alloy 201 Stud Bolt, Nickel 201 Flange Head Bolt, ASME SB564 Nickel 201 U Bolt, Nickel Alloy 201 Allen Bolt.

UNS N02201 Flange Head Bolts are especially helpful for preserving product purity while processing foods, synthetic materials, and caustic alkalis. They are also beneficial in structural applications where corrosion resistance is a key factor. The magnetic and magnetostrictive qualities, high thermal and electrical conductivities, low gas content, and low vapor pressure of Nickel 201 Bolts are further advantageous characteristics. We provide a wide selection of Nickel 201 Hex Bolts made with cutting-edge technologies to ensure design correctness.

Nickel Alloy 201 Bolt Specification

| Specifications | ASME SB 160/ ASTM B 160 |

| Standard | DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Length | 3 mm - 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Surface Treatment | Passivation /plain |

| Others Factor | OEM, ODM, ±0.03MM tolerance |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

| Place of Origin | India |

Equivalent Grades Nickel Alloy 201 Bolt

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | - | LC-Ni 99 |

Chemical Composition Nickel Alloy 201 Bolt

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties Nickel Alloy 201 Bolt

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

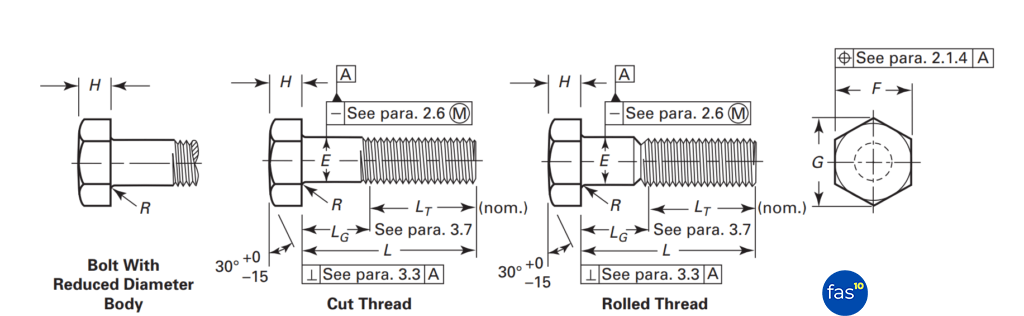

Dimensions Of Nickel Alloy 201 Bolt

Nickel Alloy 201 Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT | |||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Different Types Of Nickel Alloy 201 Bolt

Different Types Of Bolts:

ASTM B160 Nickel alloy 201 Hex Bolts

DIN 2.4068 Carriage Bolts

Nickel Alloy 201 Stud Bolts

Alloy 201 Hex Head Bolts

Nickel 201 Forged Hook Bolts

Nickel Alloy 201 Torx Bolts

Nickel 201 Countersunk Bolts

Alloy 201 Flange Head Bolts

Nickel 201 Allen Bolts

N02201 UNS 12-Point Flange Bolts

ASTM B160 UNS N02201 Eye Bolts

DIN 2.4068 Bolts

AISI Alloy 201 U Bolts

Nickel Alloy 201 J Bolts

UNS N02201 Elevator Bolt

ASTM B160 Grade 201 Threaded Expansion Anchor Bolt

ASME SB 160 Alloy 201 High Performance Anchor Bolts